What is product carbon footprint?

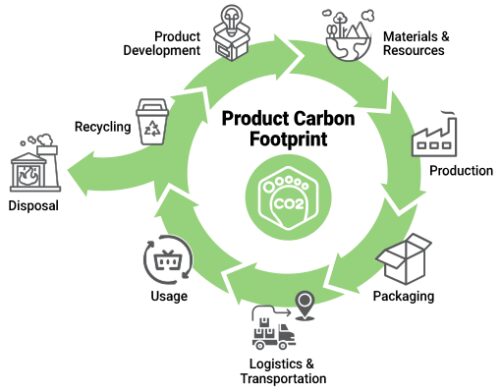

Product carbon footprint is a measure of the total greenhouse gas emissions caused directly and indirectly by a product throughout its lifecycle. This includes all stages, from raw material extraction and processing to manufacturing, distribution, use, and disposal. By assessing the carbon footprint of a product, businesses can identify opportunities to minimize environmental impact and enhance sustainability.

Understanding a product’s carbon footprint is crucial for making informed choices about the environmental impact of the goods and services we use and produce. It allows consumers to make environmentally conscious decisions, supports corporate sustainability efforts, and contributes to overall climate change mitigation.

Many organizations are implementing strategies to reduce their product carbon footprints, such as utilizing renewable energy sources, optimizing transportation and logistics to minimize emissions, and investing in more efficient production processes. Additionally, advancements in eco-friendly materials and technologies are enabling companies to innovate and develop products with lower carbon footprints.

By actively managing and reducing product carbon footprints, businesses can not only mitigate environmental impact but also resonate with eco-conscious consumers, enhance brand reputation, and contribute to a more sustainable future. But, as with many sustainability initiatives, data is at the heart of effective PCF management.

The critical role of utility data in product carbon footprint calculation

Utility data is required to determine the product’s carbon footprint. It involves a systematic process that traces the energy consumption and associated greenhouse gas (GHG) emissions back to individual products.

Here’s how the process typically unfolds:

The first step is gathering comprehensive utility data from all facilities engaged in the production process. This includes electricity usage, natural gas consumption, water usage, and waste generation data. Each type of utility data is collected from various sources, such as utility bills, meter readings, and utility providers.

Once collected, the utility data is segmented according to the facility’s different processes, production lines, or departments. This segmentation is crucial for associating specific energy consumption and emissions with the various stages of production. For instance, electricity usage in the manufacturing, assembly, and packaging stages is separated for precise attribution.

The next step is allocating the segmented utility data to individual products. This is often done using a cost-allocation method in which utility usage is apportioned based on the time and resources each product line consumes. This can be done through direct measurement (where specific meters are used for particular production lines) or more generalized allocation (based on production volumes).

With utility data allocated to products, emission factors are then applied to calculate the GHG emissions associated with each utility type. Emission factors are specific values that convert utility consumption (e.g., kWh of electricity or cubic meters of natural gas) into equivalent CO2 emissions. These factors are often derived from national or international databases providing standardized values for energy sources.

The emissions calculated for each utility type are then aggregated to determine the total carbon footprint for each product. This involves summing up the emissions from electricity, natural gas, water usage (considering the energy used in water treatment and heating), and waste management (considering emissions from waste disposal and treatment processes).

To make the carbon footprint data useful, total emissions are normalized to a functional product unit. For example, the emissions could be calculated per unit of product (e.g., per kilogram, per item, or per batch). This normalization helps compare the carbon footprints of different products and identify the most carbon-intensive products.

The data dilemma

Utility data is critical in determining the product’s carbon footprint. However, collecting utility data is very cumbersome because of its complexity. Each facility may have several utility providers that issue data in different formats and frequencies. This data is downloaded manually in most cases. Someone has to access several invoices from various utility providers every month, extract the information from the digital invoices, and type it into a standardized spreadsheet or directly into carbon calculation software. Manual processes are always error-prone, ranging from missing items to misunderstanding the information on the invoices to typos during the manual transformation.

By mapping energy consumption directly to meters at production facilities, you can accurately report on carbon footprint and better detect opportunities to reduce GHG emissions. Above, utility data integrated into SAP Sustainability Footprint Management shows the overall product carbon footprint with a drill-down into the source CO2 contributors.

Automating data collection and product carbon footprint calculation

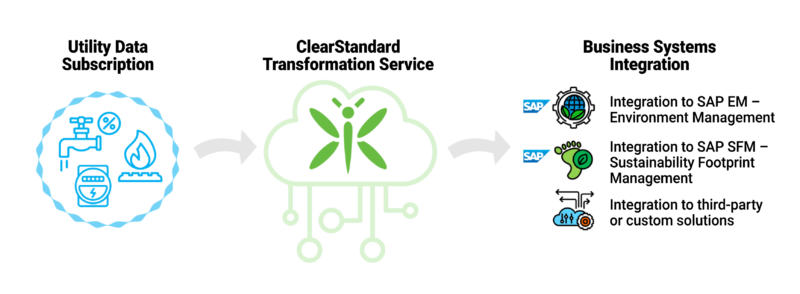

ClearStandard solves the data dilemma by hooking your business systems up to data feeds directly from your utility accounts. Moreover, you can improve the specificity of your reporting because ClearStandard lets you map meters to production lines for more accurate and timely consumption data which in turn provides more precise carbon footprint calculations.

Is ClearStandard right for you?

With thousands of utility accounts available for streaming electric, natural gas, and water usage data, it’s likely ClearStandard has you covered. Go ahead and search our database of providers or contact us for demo.